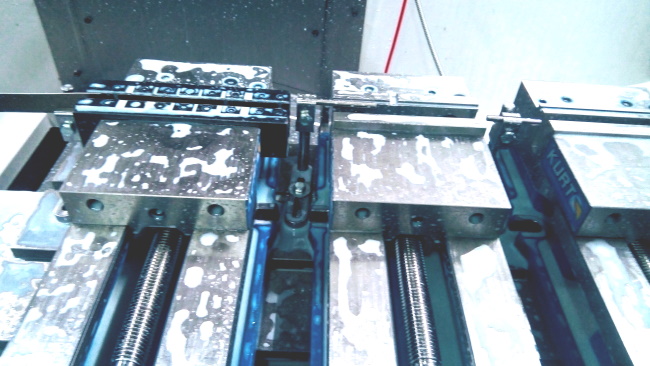

I setup the Brother Speedio mill table with 3 vises. This allows me to machine all 6 sides up to 8" X 8" X 3" [200mm X 200mm X 75mm] of 6061 aluminum plates with minimum setup changes.

This caused a problem. The current vise stops were either too big on the sides or invaded my precious milling area.

I needed something which was fast to put on and take off, required a single tool to adjust, and you don't have to bend over backwards to get at a fastener. It also had to live in a 3/4" [19mm] space between the mill vises. Simple!

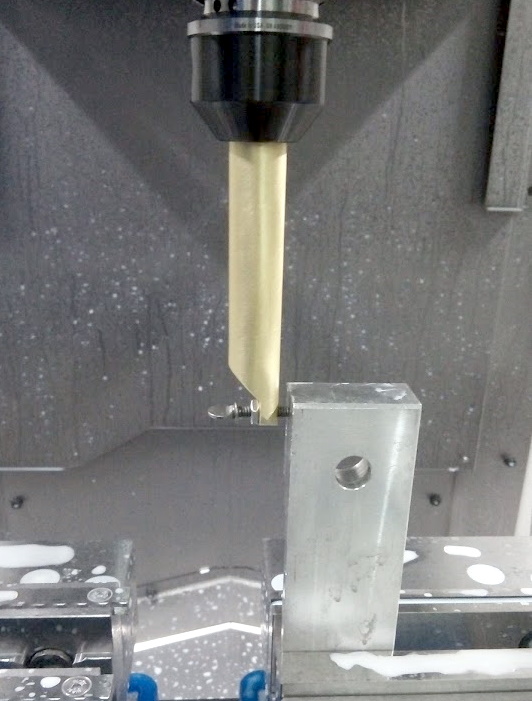

The first thing I tried was a programmable mill stop in a tool holder. The idea was to program the stop into position and set a pause for the operator to load the part. This could be done with a macro. While it does work, the M19 (orient spindle) does not have speed control, and the Brother Speedio as the name implies is a very fast machine! This design went on the back burner.

I went through several additional designs.

The drop in tee slot design seem promising so I broke it into two problems. Tee nut base and upper slide mechanism.

I borrowed some cad, modified it, and tested the tee nut base. It worked!

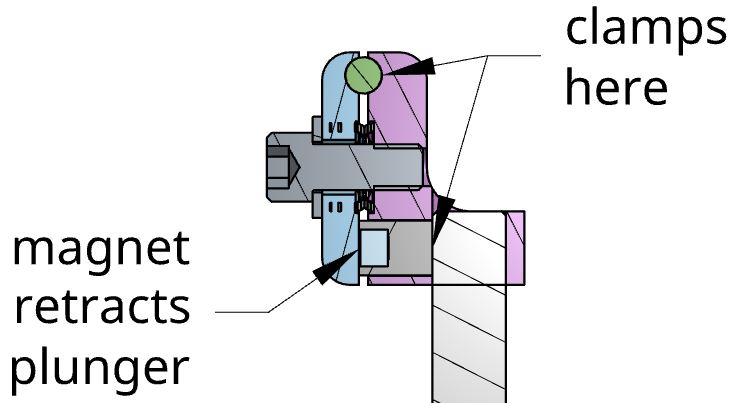

For the upper slide I wanted something to clamp both rods with one fastener. This is what I came up with from the bits I had on hand.

It clamps both vertically and horizontally with one fastener!

I machined the parts.

It worked!

We may do several setups in a day. Making each setup faster saves a lot of time!

They also fit nicely between all 3 vises.

The end effectors are pretty easy to make. Just cut off some 1/4 drill rod or cut up some 16 gauge sheet metal.

Thanks for looking! There are more pics, CAD, and CAM here...